In 1957, the company began to produce chains. In those days, chain production required machinery and manual labor. After forming the chain link thru chain forming machine, the surface of the chain must be cleaned with chemical solution. Then the chain is conveyed to be welded link by link. By hand welding method, with positioning the chain link at the shelf space of the machine and then press on foot pedal so that copper rods move down to connect the joint of each chain link. After that, the weld should be smooth. With the hand to position the weld of the chain at the shelf space of the machine, then press foot pedal to make the cutter cut off the crack at the weld link by link until it became a ready-to-use chain. This process was used to produce the chain until year 1977. During this time, the company used symbols  as a trademark for normal grade steel chain. This chain is for use such applications as guard rails, tie down , load binding, logging, and general purposes other than overhead lifting

as a trademark for normal grade steel chain. This chain is for use such applications as guard rails, tie down , load binding, logging, and general purposes other than overhead lifting

History Of The Company

In 1957, Tang Khun Huad Company was founded as a small business by Mr. Bakkung Saetang in Khlong Toei District, Bangkok. At that time, the company engaged in the production of steel chains, springs, steel cabinets and desks, and color-coated slotted angle for shelves.

-

YEARS 1957 TO 1977

-

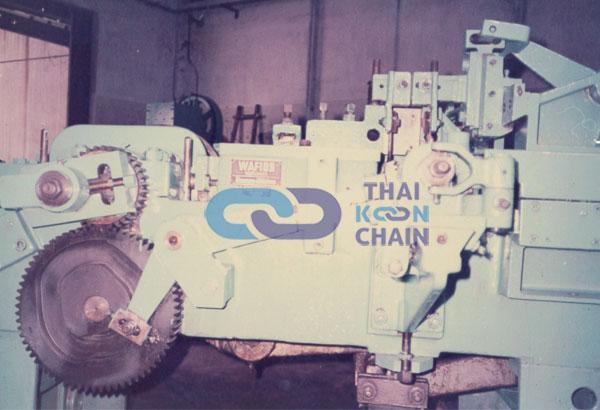

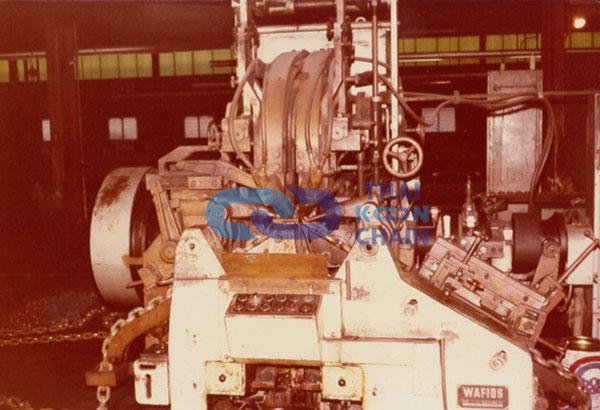

YEARS 1978 TO 1997

In 1978 to 1997, Automatic chain welding machines were developed. The machine will cut off the crack at the welds immediately in order to make the weld smooth. However, the chain link could not be welded one after the other in succession. Therefore two consecutive chain welding machines are required in a sequence so that the chain link is welded every single link. This chain welding machines were imported from Germany to ensure that the chains could be produced to conform with international standards. During this time, the company added symbols

as a trademark for this chain. Due to lack of marking manufacturer ‘s symbol and grade down to the chain link, Therefore it does not meet the International standards specifications. So it is set as the standard of the company itself. This grade is comparable to grade 30 chain-American standard, grade M-Japanese standard and grade L- Australian Standard.

as a trademark for this chain. Due to lack of marking manufacturer ‘s symbol and grade down to the chain link, Therefore it does not meet the International standards specifications. So it is set as the standard of the company itself. This grade is comparable to grade 30 chain-American standard, grade M-Japanese standard and grade L- Australian Standard. -

YEARS 1998 TO 2017

In 1998 Automatic chain welding machines has been developed so that the chain link is welded every single chain link in succession .

In 2007 Chain forming machine and chain welding machine were combined into one automatic machine. After forming the chain link, the joint of each chain link was welded right away.

In 2011 Management System Standard ISO 9001 CERTIFIED.

In 2017 the company imported Marking Machine, Calibrating Machine, Hardness Tester, Heat Treatment System and Cutting Machine. These are especially for the production of all grades of chains to conform with internatioanal standards such as ASTM, JIS, EN and AS etc. The company added symbols as a trademark for this chain. It is defined as international standard grade steel chain.

as a trademark for this chain. It is defined as international standard grade steel chain.

-

YEARS 2018 TO 2021

In 2018 Established Thai Koon Chain Company on a new area to support the development of international quality chain production.

In 2020

January 2020 Thai Koon Chain Company has exported international standard steel chains for foreign countries in term of OEM (Original Equipment Manufacturer). The company is the first OEM in Thailand who supplies international quality chains G30, G43, G70, G80, G100 to the United States. It is recognized internationally for the first company in Thailand and South East Asia region that can successfully produce international standard chains.

March 2020 Cold Drawn Steel Wire For Concrete Reinforcement TIS. 747-2531 CERTIFIED. Cold Drawn Steel Wire is used for reinforcement in prestressed concrete works such as reinforced concrete pipes for underground pipe work for underground electrical wiring and general concrete work.

May 2020 Exported international standard steel chain to South Korea.

In 2021 MIT (Made In Thailand) CERTIFIED for Cold Drawn Steel Wire For Concrete Reinforcement. Imported high quality wire drawing machine and chain bending machines from Germany to support the production of international standard chains in particular.

-

YEARS 2022

TIS certification for Thailand quality products.

MIT certification for products made in Thailand.

White Factory certification for Drug Prevention and Solution Program.

Green Industry certification Level 2 for Environmental Impact Reduction Campaign.

CARBON FOOTPRINT product certification for reducing the amount of greenhouse gas emissions from corporate activities.

Safety, Occupational Health, and Work Environment Certificate at Gold Level

SOLAR ROOFTOP Clean Energy certification for Solar Rooftop Power Generation System.

Our products are produced using 50% solar energy, reduce electricity consumption up to 65%, reduce carbon dioxide, reduce global warming and be environmentally friendly.

VISION MISSION

TKC CONNECTS THE WORLD

GO Green With Our Products

VALUE

BRAND

Thai Koon Steel Group

Go Green With Our Products

Thai Koon Chain

TKC Connects The World

Thai Koon Chain

Chain Of Life

MANAGEMENT POLICY

We will continually improve the efficiency and potential of our employees in order to create the best efficiency in the production of goods and services. The aim is to provide a quality service system throughout the organization.

Quality and Environment Policy

Create a valuable business

With an environmentally friendly process

Develop technology readiness

Caring for the environment and community